In this article, we are going to discuss how the IoT contributes to the manufacturing industry and how it benefits the business in different ways. Modern technology has brought manage gifts to businesses and IoT is one such benefit.

With the use of modern technology, one can use advanced analytics to take care of the activities. If real-time insights are used, they can help to increase production and help employees to take correct decisions at the right time.

“The use of IoT helps to bring both efficiency and productivity in parallel to your business.”

The researchers and experts suggest that IoT will have a huge impact on the manufacturing industry by providing managed activities, maintenance, asset management and a lot more to bring a new age of growth and competitiveness.

The manufacturing industry experts are suggesting investing in the IoT, to grab the benefits, efficiency and productivity. Also, the use of IoT in your business helps in expansion and growth in future. Below are a few major benefits explaining how the IoT has contributed to the manufacturing industry and what are its benefits.

Asset Maintenance

A lot of expense is made in maintaining the activities and machines. But, if the maintenance is following on time, it can prevent a lot of expenses and pauses on the processes. Also, if the companies can understand and detect the downtime of machines, they can substantially decrease the costs associated with them. The IoT uses sensors, cameras and analytics reports to maintain the timelines and glitches in the machines. This helps to plan for the strategic timelines that can repair the in-between breakages and avoid the work being stopped.

The manufacturers use the IoT to have competent, vibrant and automated activities where the schedules are maintained rather than only relying on the responsible personnel for the job. IoT makes sure that the processes are well-planned and provide huge savings along with reducing the failure as well as increasing the machine life.

Real-Time Activities

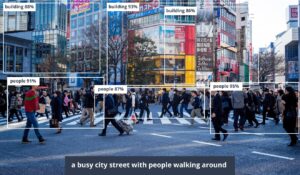

The IoT assets are used by the manufacturing companies to connect the machines and systems to bring the latest shift in real-time asset calculation. The connected assets always prove to be better in terms of reliability, safety and compliance that help to make better decisions in terms of products. The remote manufacturing processes use asset monitoring through the sensors to track the production process in real-time and keep sending the status to required personnel. The personnel can easily generate reports and understand the situation.

Apart from this, the IoT can also control and manage assets to provide enhanced production and activities with proactive and timely decisions. The assets tracking allows easy monitoring and control of machines and products along with maintaining inventory and quality.

Business Intelligence for Processes

When the businesses are connected with machines and equipment, the manufacturers can easily generate intelligent networks having the facility of quick and easy communication, coordination among the employees with little requirement of their physical availability. The organization can manage the data and assets remotely and turn systems into applications.

The IoT helps to provide proactive views of the data and help to solve problems quicker. The IoT enabled machinery helps to connect the machines with the business intelligence, which help to generate real-time insights and send them to the stakeholders that enable them to manage the unit and products.

Conclusion

These were a few points that show how IoT has contributed to the manufacturing industry and how it has brought advanced changes in the working of the industry. It not only manages and connects the machinery but also coordinates the employees to work efficiently and accurately.